Horstman Services

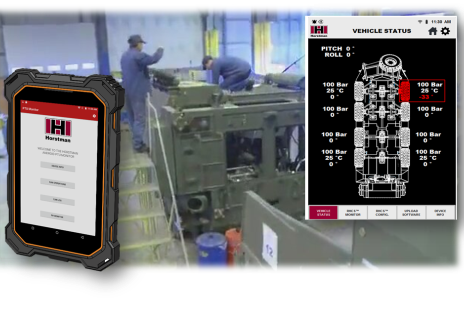

Horstman Diagnostics

The Horstman line of Diagnostic equipment enables the maintainer to interrogate our various advanced electronic system offerings via direct connection to sensors/solenoids or via CANBus communication.

The Horstman line of Diagnostic equipment enables the maintainer to interrogate our various advanced electronic system offerings via direct connection to sensors/solenoids or via CANBus communication.

This reduces Mean Active Maintenance Time (MAMT) in troubleshooting and diagnostic and increases fleet availability. The diagnostic equipment includes:

- System and Acceptance Test

- Software updates

- Fault finding using automated hardware diagnostics, Wiring integrity checks and independent wheel station interrogation

CANBus logging and data analysis

Android Based Software

- Large open source platform for rapid feature development

Rugged Tablet

- Ease of use, allowing the maintainer flexibility to work in a safe working environment

Fault finding to LRU level

- Validate controller, wheel station sensor and valve functionality independently of complete system Real-time sensor outputs for on-vehicle calibration

RHCS™ Health Monitoring

- On vehicle system monitoring to identify preventative maintenance opportunity

Application

Wheeled

ATV

CAV

Tactical

Towed

6x6 8x8

Mining

Agri

Tracked

<24T

25-35T

Special

36-90T

Accessories

- Cable set (vehicle specific) and system interface module

- Gas Charging Kit and Hydrobooster for Hydrostrut installation

Downloads

Contact

Any questions to our company?

You are more than welcome to explore our website. In case you have any questions and demands in regard to our company, get in touch and send us an email.

HORSTMAN Group