Mobility Solutions

Horstman Additive Manufacturing

Additive and reductive manufacturing techniques.

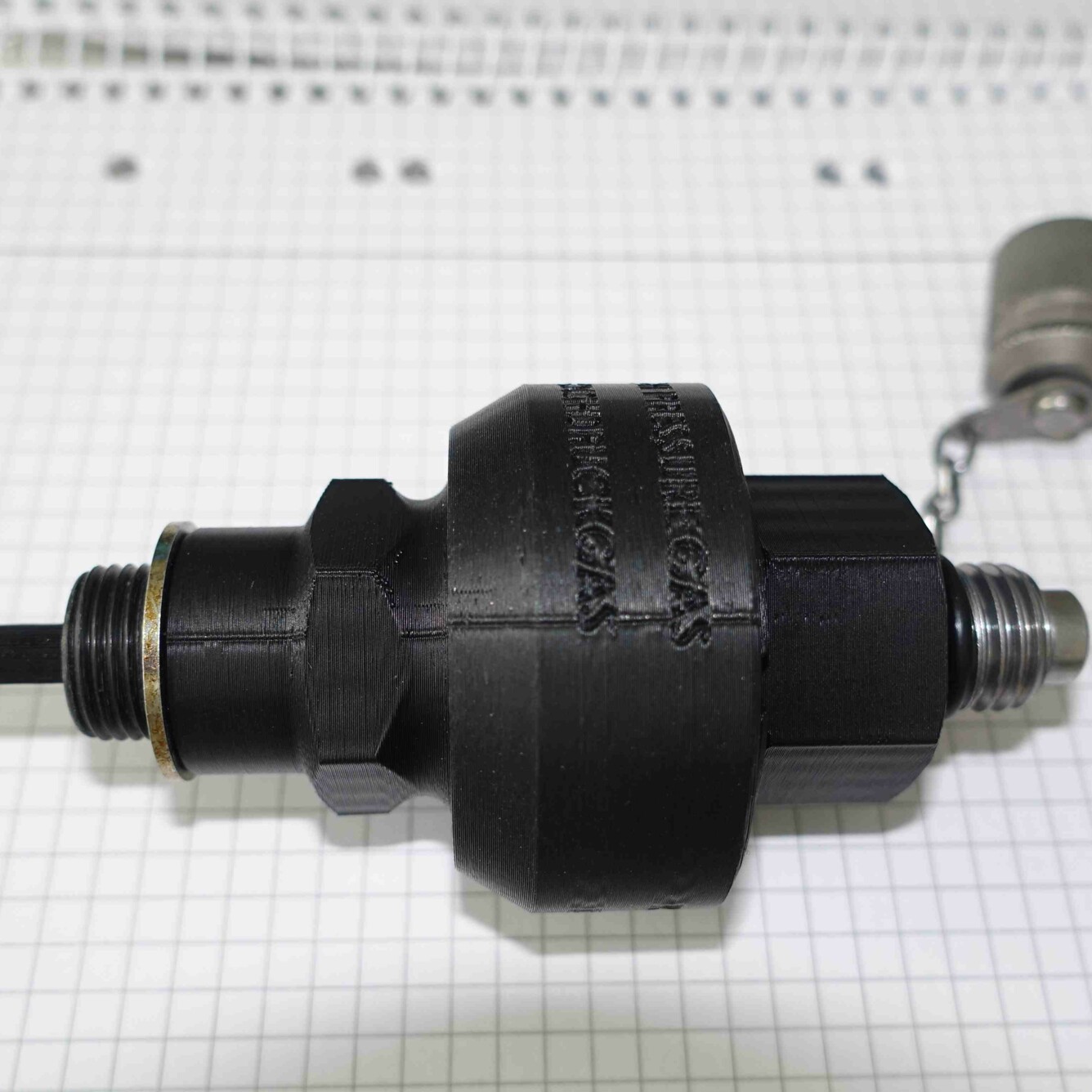

Additive and reductive manufacturing techniques are used to produce high-performance lightweight engineered solutions.

Horstman also uses additive manufacturing to produce space claim and functional interface check models for integration and maintainability checks before committing to the manufacturing of objective hardware.

Our manufacturing team advise and guide customers on the best use of the technology to produce advanced lightweight components, reducing lead times and enhancing functional performance.

Advanced materials

- Lightweight high strength titanium materials, with optimised geometry

- Use of conventional materials to reduce weight and minimise cost

Rapid manufacture

- Established supply chain management to produce additive manufactured components

- Rigorous quality inspection and control to ensure product consistency

Testing

- In-house functional and performance testing of components

- Established sub-contract testing resource and test plans to demonstrate component strength, durability and failure modes

Analysis

- Established analysis techniques to ensure components suitability before committing to manufacture of hardware

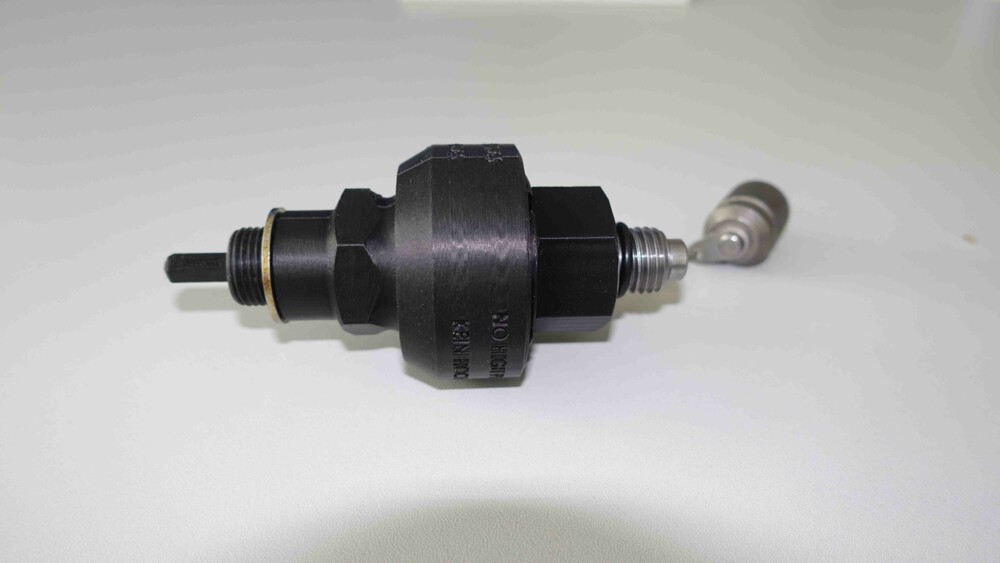

Pressurised systems

- Extensive experience of rapid manufacture of high pressure oil and gas components, including pressure vessels, pistons, rams, damper components, valves, bodies, fluid transfer ports, and structural components

Application

Wheeled

ATV

CAV

Tactical

Towed

6x6 8x8

Mining

Agri

Tracked

<24T

25-35T

Special

36-90T

Accessories

- Virtual training aids, product 3D fly through

- AM tool, fixture and die making

Contact

Any questions to our company?

You are more than welcome to explore our website. In case you have any questions and demands in regard to our company, get in touch and send us an email.

HORSTMAN Group